Principle & Process

A completely unique solution that is flexible to the composition of the input waste material.

- Home

- BlowDec Innovation

- Principle & Process

The real innovation of the device is a special process chamber, the BlowDec reactor. Its construction resembles a hammer mill. The reactor consists of a gas-tight cylindrical chamber and a rotor carrying wear-resistant blades. The rotating movement of the rotor in the process chamber is achieved by an appropriate motor.

The rotating movement of the rotor blades in the reaction chamber causes intense mixing and swirling of the reaction mixture composed of a solid inorganic substance (sand) and an organic component (solid/liquid hydrocarbons). As a result of the friction of the rotor blades against the reaction mixture and the emergence of hydrodynamic forces, heat is generated.

At the same time, particles of a solid inorganic substance, such as sand, create a swirling hot "bed" with fluid properties near the cylindrical wall of the chamber. A significant role is also played by the considerable total surface of solid particles with an area of several thousand square metres, which represents a highly efficient heat exchange and mass transfer surface.

A significant part of chemical reactions and physical processes take place in the fluidized bed. The most important chemical events taking place in a swirling fluidized sand bed are cracking reactions of all types – thermal and catalytic, as well as their combinations.

Primary reaction products of the cracking of larger molecules enter recombination and isomerization reactions. Some plastics undergo random depolymerization (polyolefins – HDPE and LDPE, PP), others non-random depolymerization (polystyrene).

The majority of heavy and solid hydrocarbons are cracked into lighter components in the sand fluidized bed, which subsequently evaporate and leave the reactor chamber in the form of process gas.

At the same time, substances with a lower boiling point - water - evaporate. Due to the fact that all physical and chemical events in which energy and matter are transformed take place simultaneously in a single work stage, the process is extraordinarily energy efficient.

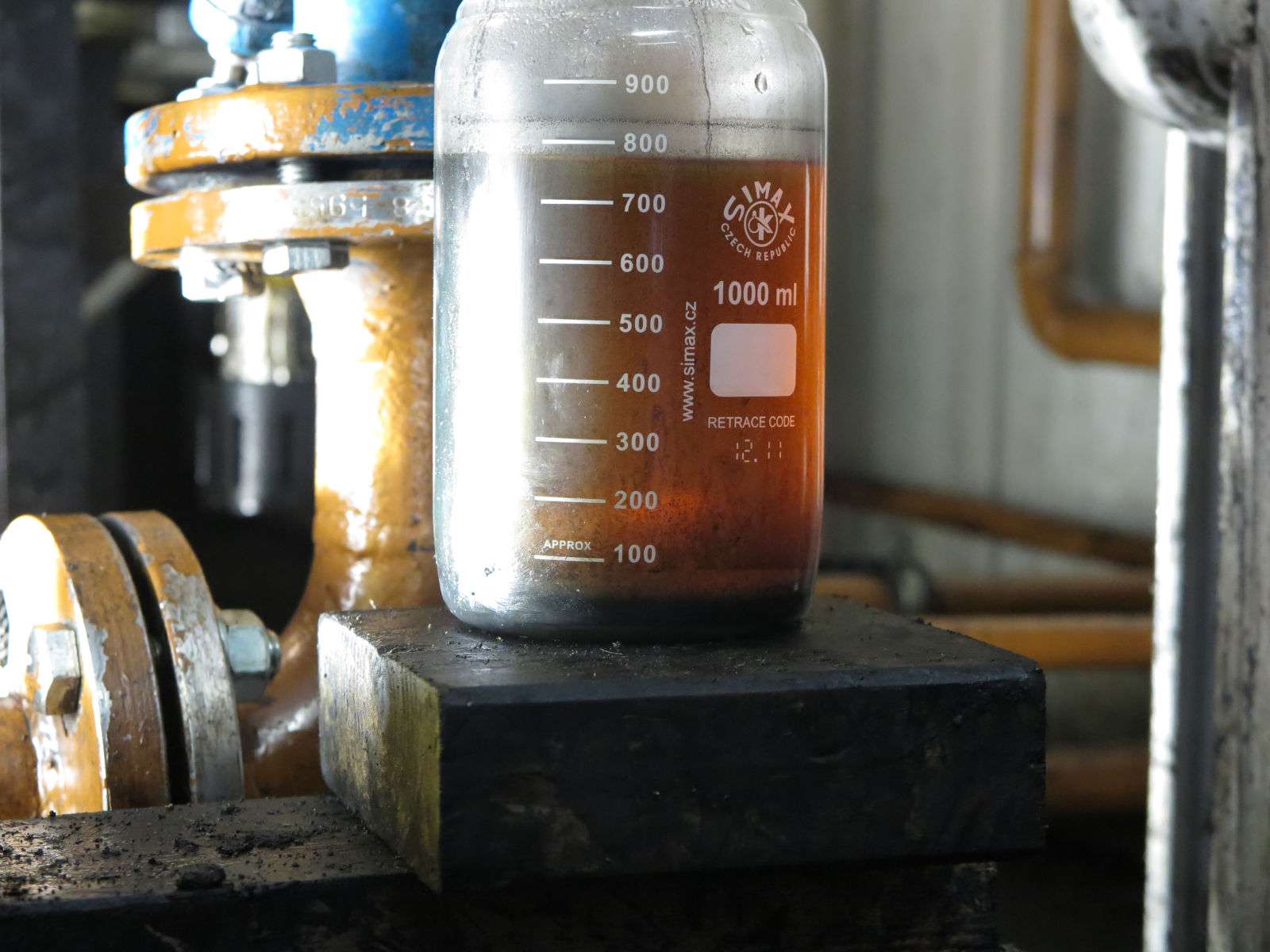

The obtained hydrocarbons mostly correspond to high-quality energy heating oil with low or zero sulphur content (from plastics).

During the BlowDec® process, physical and chemical processes occur and as a consequence there is a 100% conversion of hydrocarbons together with substantial change in the quality of product compared to the original feedstock.

At the same time, there is an effective separation of the substances that formed the original waste material, while obtaining pure valuable oil without pollutants, separated waste water and (if present) a solid phase in which parts of inorganic pollutants are firmly fixed in a mineralized form. Nitrogen and sulphur oxides are not produced.

In short, the BlowDec® technology allows for processing, recycling and upgrading of crude oil based waste products with unparalleled results.

For results and more information